The uniqueness of this project is that we have taken a standard process and studied every element with the chain of delivery. We have then improved every aspect of this chain, but using highly innovative solutions based upon a wide range of engineering solutions.

Within a competitive industry clients need to be getting fast and accurate results delivered in a way that suits and helps them. This project started by looking at our booking process, the organization of test equipment and our data processing methodology. The second goal of this project was to reduce our carbon footprint and to look at opening new markets in the field of sound testing and measurement.

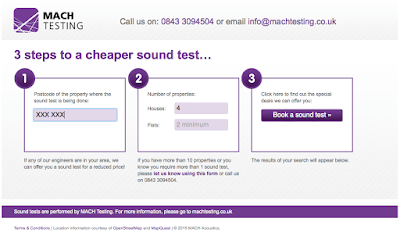

Booking System

Various staff taking calls and booking them into a diary, is that as good as it can get? The solution has been to create a web based data system, containing information relating to test locations, our equipment, cars and engineers available for testing. By cleverly arranging this database, our staff and clients can use our web based booking system, which provides more competitive testing rates on the grounds that we know that we are in a customers area. Since the location of every sound test, meeting and environmental noise assessment is sorted though a single booking system, our efficiency is increased dramatically.

In effect, our system works the opposite way to Easyjet, hence the name Easy Sound Testing. The maths behind this relatively simple idea is complex, however we have shown that we are reducing the cost to clients and have cut our testing mileage by more than 15%. We are now looking to increase this figure to 25%.

Data Processing

Issuing reports on site brings many advantages, including client satisfaction and the ability to investigate and support clients in the case of failures. The time advantage this brings to the tester is also important, improving accuracy and increasing profitability as the report is generated immediately.

To do this, we have developed our own software. The software works by taking on site data relating to room dimensions, test locations and file data numbers on the sound level meter. Upon the completion of the test, the software uploads raw excel test data from a Norsonic, NTI or B&K sound level meter and combines it with the site notes initially entered into the software. The results being a file containing sorted test data combined with on site test information, as well as generating test certificates and tables of results.

By developing an intelligent system MACH has not only reduced its carbon footprint considerably but clients also benefit with a more intuitive system that they can take more control of themselves.