Case Study – Installation of Attenuators at Bristol University

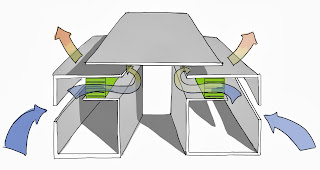

MACH Acoustics, in collaboration with Capita Architects have been involved in the design of Bristol University’s Graduate School refurbishment. The need for sustainable and low-energy buildings has led to a natural ventilation scheme being carefully implemented into the design. The scheme involves air being brought into the classrooms through open-able windows and discharged into the main corridor via cross-talk attenuators, as shown within the section below. The stack effect, caused by the height difference between the air in-let windows and the air out-let, naturally drives the hot air out of the building. Cowlin Construction, the main contractor, has now handed over the project to the University and has therefore asked MACH Acoustics to support the final design and installation of the crosstalk attenuators.

The cross-talk attenuators limit the transfer of noise between the classrooms and corridors, therefore maintaining privacy but allowing air flow. BB93 requires ventilators in corridor walls to achieve a weighted element-normalized level difference (Dn,e,W) of 39dB. To achieve this target in the new Graduate School, MACH Acoustics have designed 1500mm long, NAT Vent Attenuators which have been installed into bulkheads between the classrooms and the main corridor.

For the Attenuators to be efficient, they have to be acoustically enclosed so the noise cannot bypass the attenuators. The best solution is therefore to install the attenuators into a pre-constructed duct. The ducts can be made of any material as long as it provides sufficient sound reduction. In this case the ducts have been constructed using plasterboard for cost, time and convenience reasons. The photos below show the different stages of the construction to install the bulkhead and ducts.

|

| Construction of the Duct |

The NAT Vent attenuator is a highly efficient attenuator designed specifically for natural ventilation. Its foam design makes it the most flexible and high performance attenuator on the market for this purpose. The NAT Vent Attenuators used in the Graduate School are 1500mm long with a free area of 50%. The photos below show the installation of the foam attenuators into the bulkheads. Each attenuator is made up of 2 rows of 5 foam tiles stacked on top of each other to form the channels. The tiles are then simply slid into the ducts.

|

| Installation of NAT Vent Attenuator |

MACH Acoustics specified the partition to perform to a (Dn,e,W) of 39dB. On-site testing following installation resulted in the partition achieving this and conforming to BB93 requirement. Considering the NVA as a separate element, it was shown to perform over it’s quoted attenuation.

Download this case study (pdf)